Galvanising Process Info

Copyright 2006 Ultra Building Products. All rights reserved.

The Coating

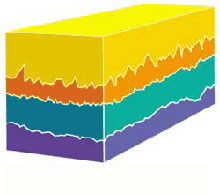

When the reaction between iron and zinc has virtually ceased and the article taken out of the galvanizing bath complete with its outer coating of zinc, the process is complete. In reality there is no demarcation between steel and zinc but a gradual transition through the series of alloy layers which provide the metallurgical bond.

Coating Thickness

Coating thickness' are normally determined by the steel thickness and are set out in BS EN ISO 1461. There are three exceptions to this rule, the first produces a slightly thinner coating, the other two increase it.

Centrifuged Galvanized Coatings

This process, covered in BS EN ISO 1461, is used for galvanizing threaded components and other small parts. The parts, after preparation, are dipped in the molten zinc in a perforated basket. After the coating has formed this is spun at high speed, to throw off surplus zinc to ensure a clean profile. Minimum average coating weights for centrifuged work are identified in BS EN ISO 1461 and in BS 7371 Part 6.

Welcome To Ultra Building Products!

The Company is a diverse manufacturing enterprise based in Newtownstewart, County Tyrone, supplying quality products and services to a variety of industries including the Construction Industry, Farm, Home and Garden.

Ultra are specialists in Hot-dip, galvanising services.